เครื่องบด

Food-เครื่องบด

- สิ่งที่แนบมา0

- ดู

- 2929

Method and Specialty

When the

compressed air passes the feeding spray equipment and the smashed material gets

into the smashing room, the smashing spray nozzle on the periphery of the

smashing room spray supersonic speed airflow so that it can make the material smashed

with the airflow's high speed lashing, the material's colliding and friction

each other. Then grading tube will separate the coarser pellets from others and

the coarser pellets will circuclate back to the smashing room to be smashed

again. After the inter sealed cycled smashing, we can get the well-distributed

supertiny powder at the material outlet.

It's

suitable for dry supertiny technology. Because the speed of the impact is high,

(more than 2.5 mach), it's easy to get 1-10 micro pellets. According to the

material's property, it also can get the pellet less than 1 micro sometimes Because

there is a sealed grade machanism in the pulverizer and the coarse pellets in

the products instantly can be smashed cycledly, the products are made up of well-distributed

products whose pellet radium distribution's scopeis limit The equipment has

many advantages such as short smashing time, simple structure, convenient

operation and repairment, small volume, low(72 decibles) and no vibration.

It has a

high efficienty when smashing. It can have a continuous smashing and it can keep

the smashing product's purity.

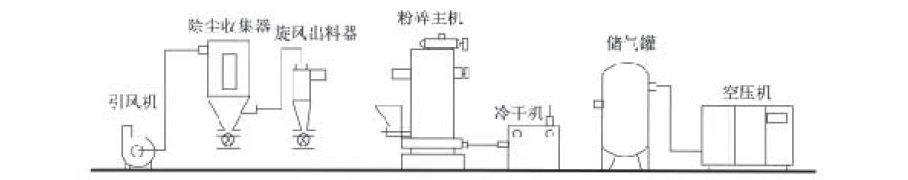

Flow chart

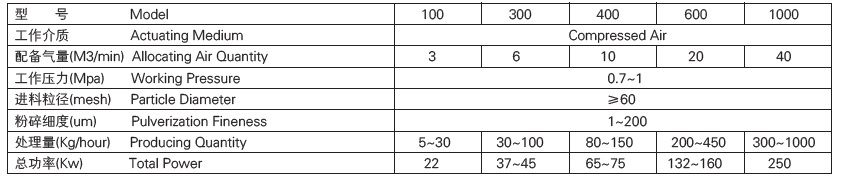

Specification

แก้ไขข้อคิดเห็น

ป้อนรหัสผ่านของคุณเพื่อแก้ไขโพสต์

ลบความคิดเห็นลบโพสต์

ป้อนรหัสผ่านเพื่อลบโพสต์